Choosing the correct bit head design for Down-The-Hole (DTH) drill bits involves a systematic approach that considers geological conditions, bit characteristics, and operational parameters. Here’s a structured guide to making the right choice:

1. Assess Rock Formation Properties

– Hardness:

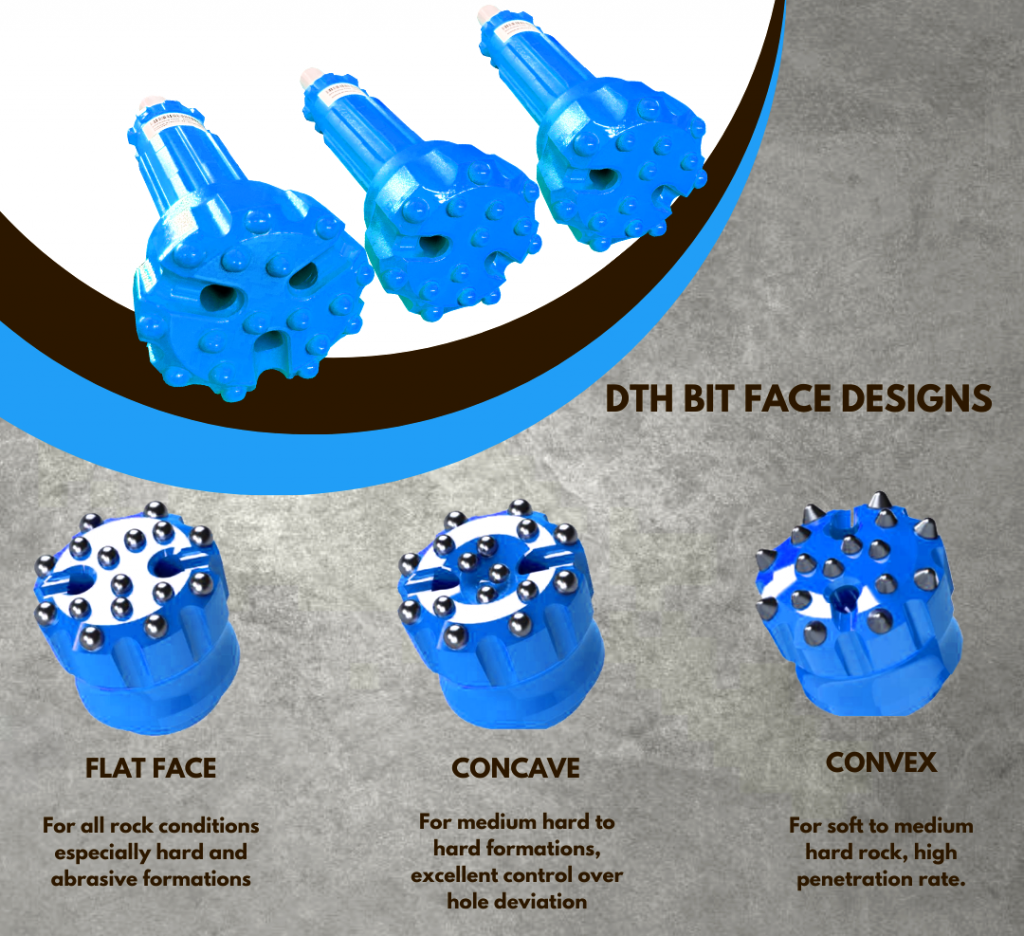

– Hard Rock (e.g., granite, basalt): Opt for a convex head design with fewer, larger, hemispherical buttons (180° tip angle) to concentrate impact energy and resist wear.

– Soft to Medium Rock (e.g., limestone, sandstone): Use a concave head design with more, smaller buttons (130–150° tip angle) for efficient cuttings removal and reduced balling.

– Medium to Hard Rock: Consider a flat head design as a versatile option.

– Abrasiveness: Select materials with high wear resistance (e.g., premium tungsten carbide buttons, alloy steel body with robust heat treatment).

2. Button Configuration

– Number and Size:

– Hard rock: Fewer, larger buttons for focused impact.

– Soft rock: More, smaller buttons for broader coverage.

– Angle:

– Steep angles (hemispherical) for hard rock durability.

– Sharper angles for soft rock to enhance cutting efficiency.

– Gauge Protection: Ensure robust outer buttons to maintain hole diameter and prevent premature wear.

3. Flushing System Design

– Ensure adequate flush ports for efficient cuttings evacuation. Concave heads may offer better clearance, while convex heads require strategic port placement to avoid clogging.

4. Material and Durability

– Bit Body: Use high-alloy steel with proper heat treatment (quenching/tempering) for toughness.

– Buttons: Tungsten carbide with optimal cobalt content (e.g., 6–12% cobalt) to balance hardness and impact resistance.

5. Drilling Parameters

– Impact Energy: Match bit design to rig capacity (e.g., convex heads for high-energy rigs in hard rock).

– Rotation Speed: Adjust button layout to prevent uneven wear at high RPMs.

– Feed Pressure: Ensure bit design aligns with optimal penetration rates without causing excessive wear.

6. Cost and Longevity

– Evaluate total cost of ownership: Higher initial cost for durable bits (e.g., convex heads in hard rock) may reduce long-term expenses through extended lifespan.

7. Consult Manufacturer Guidelines

– Leverage manufacturer expertise for rock-specific recommendations and consider field trials to validate performance.

8. Environmental and Operational Factors

– Hole Diameter: Larger bits may require more buttons and reinforced gauge protection.

– Drilling Depth: Deeper holes may need enhanced flushing and wear-resistant materials.

Summary Table

| Factor | Hard Rock | Soft/Medium Rock |

|———————–|————————–|————————–|

| Head Profile | Convex | Concave/Flat |

| Button Type | Hemispherical (180°) | Sharp Angle (130–150°) |

| Button Count | Fewer, Larger | More, Smaller |

| Flushing | Strategic Port Placement | High Clearance Design |

| Material | High-Cobalt Carbide | Standard Carbide |

By integrating these factors, you can select a DTH bit head design that optimizes penetration rates, minimizes wear, and reduces operational costs. Always validate choices with field testing and manufacturer input.